Introduction

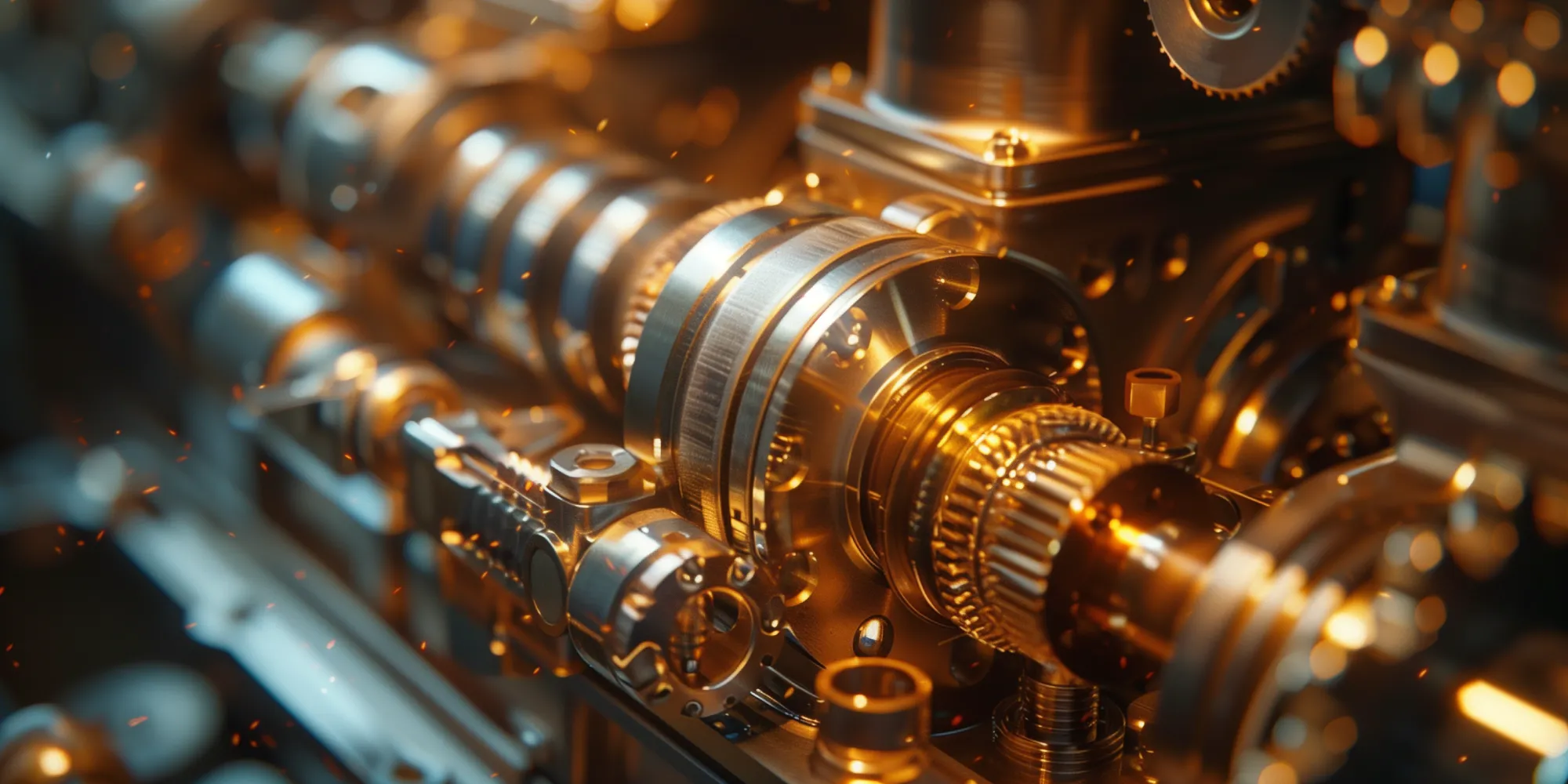

Efficient operations are the backbone of industrial success. Lubricants and additives play a pivotal role in minimizing friction, reducing energy loss, and extending equipment life. This article delves into how these solutions significantly improve operational efficiency while lowering costs.

1. Minimizing Friction and Wear

a. Reducing Energy Loss

Friction is a primary cause of energy inefficiency. Advanced lubricants form protective layers, reducing energy waste caused by friction.

b. Prolonging Equipment Lifespan

Wear and tear are inevitable, but the right additives prevent degradation. Anti-wear agents and stabilizers enhance durability, leading to fewer replacements.

c. Smoother Operations

Consistent lubrication ensures smooth machinery function. This reduces vibration, noise, and operational stress.

2. Enhancing Performance Under Extreme Conditions

a. High-Temperature Stability

Industrial processes often involve extreme heat. Lubricants with thermal resistance maintain effectiveness, preventing breakdowns under high temperatures.

b. Load-Bearing Capacity

Heavy equipment requires lubricants with high load-carrying capabilities. These solutions ensure stability and reduce downtime.

c. Resistance to Contamination

Contaminants like dust and water can compromise efficiency. Lubricants with protective additives prevent contamination from impacting performance.

3. Streamlining Maintenance Processes

a. Extended Maintenance Intervals

Quality lubricants reduce the frequency of maintenance. This saves time and resources, keeping production on schedule.

b. Predictive Maintenance

Modern lubricants enable predictive analytics. Sensors monitor lubricant condition, allowing proactive maintenance.

c. Simplified Application

Efficient application methods like automated lubrication systems save labor and ensure consistent coverage.

4. Boosting Energy Efficiency

a. Lower Power Consumption

Reducing friction leads to lower energy consumption. This not only saves costs but also supports sustainability goals.

b. Optimized Heat Management

Lubricants with superior thermal properties dissipate heat efficiently. This prevents overheating and ensures consistent performance.

c. Reduced Carbon Footprint

Energy-efficient operations reduce emissions. Bio-based lubricants further enhance environmental benefits.

5. Industry-Specific Efficiency Gains

a. Manufacturing

High-speed equipment benefits from lubricants designed to minimize downtime and maximize throughput.

b. Automotive

Engine-specific lubricants enhance fuel efficiency while meeting emission standards.

c. Energy Sector

Wind turbines and power generators require durable lubricants to withstand constant use and harsh conditions.

Conclusion

Lubricants and additives are more than just maintenance tools—they are key drivers of operational efficiency. From reducing energy consumption to extending equipment life, these solutions transform industrial performance. Investing in the right products ensures smoother operations, reduced costs, and greater productivity.